Discharge Lamp Technology

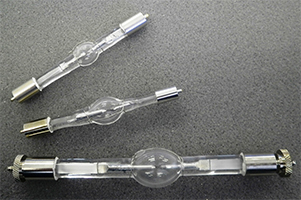

KHD Metal Halide Lamps

One of the main applications of metal halide lamps is movie and TV shootings. Consistent performances in characteristics, such as color temperature that closely replicates natural sunlight, and higher color rendering properties, are required throughout the lifetime. With its unique technology, KHD metal halide lamps are designed and crafted to suit customers intended purposes.

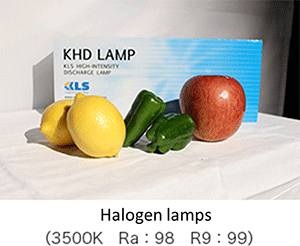

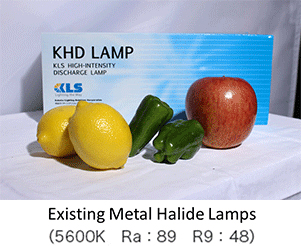

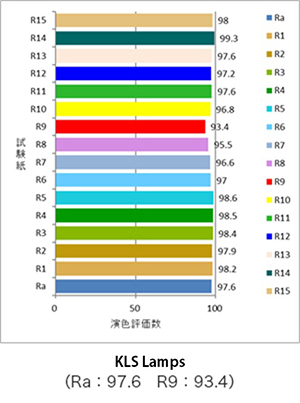

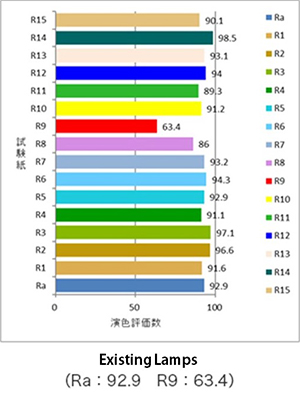

Color Rendering Property

With the development of technologies, the color rendering of metal halide lamps have been improved but they are still weak in R9 (red) rendition.

KLS has established a unique technology for metal halide sealing and arc tube design to maximize the color rendering.

- Comparison of Color Rendering Index

Reducing Variations

Maintaining consistency of color temperature, color rendering and color tone are critical for film shooting lighting. To overcome these technical challenges, we have identified risk factors and established a unique custom lamp design and a manufacturing process.

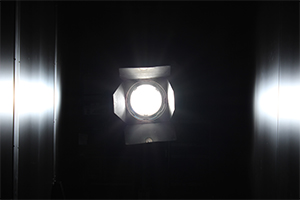

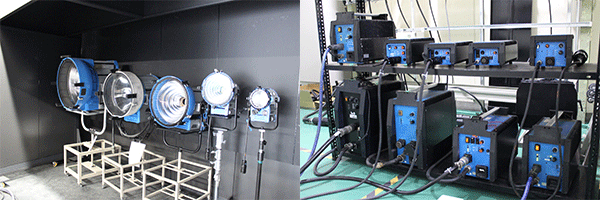

- Color temperature, rendering, tone measurement

- Evaluation Fixtures

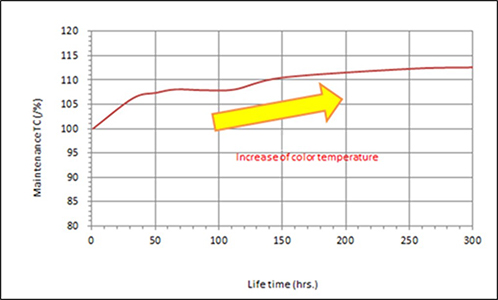

Stabilizing Characteristics of Operating Lamps

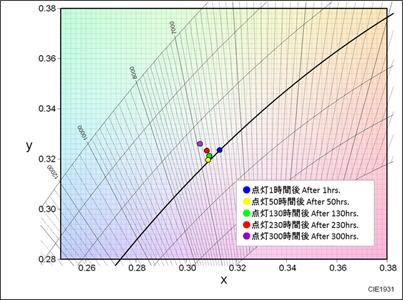

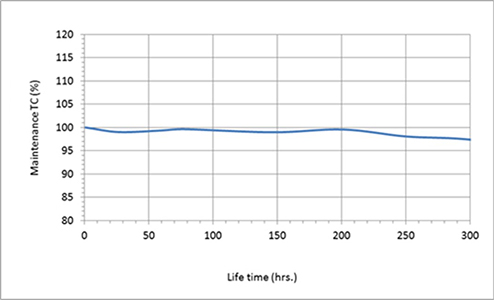

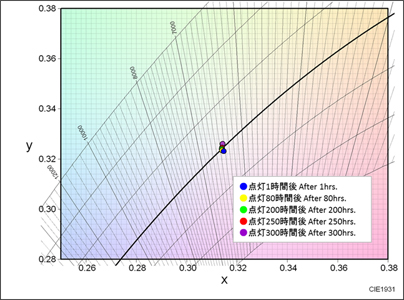

Color temperature and color tone of metal halide lamps can change as lamp life progresses. This is mainly due to blackening and devitrification of arc tube and/or physical property change of sealed metal halide inside an arc tube.

- TC values over lifetime

- Chronological change of chromaticity coordinate

KLS metal halide lamps are designed to produce stable color temperature, color rendering and color tones, not only at initial stage, but throughout its lifetime.

- TC values over lifetime - proper design

- Chronological change of chromaticity coordinate proper design

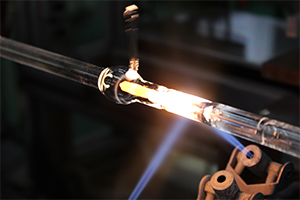

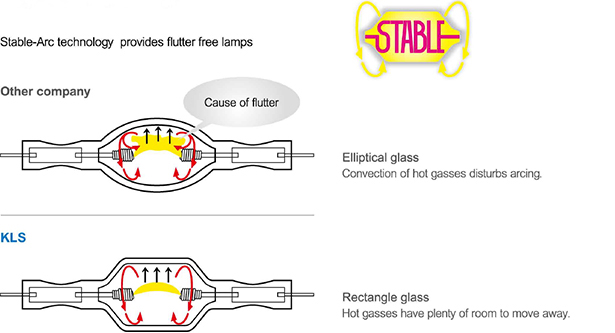

Arc Stabilizing Technology

Metal halide lamps are arc discharge lamps and the light emitted from the lamp can occur

flickering or fluttering due to an unstable electric arc or reverse gas flow inside a tube. At KLS, we have the technology to manufacture a tube that can minimize these technical problems.

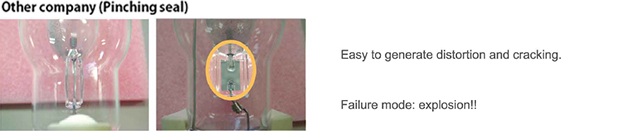

Preventing Explosions

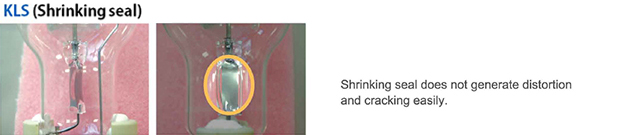

Explosion of lamp is fatal defects and should never happen.

KLS applies shrink sealing method for tubes to prevent risks of explosion.

- Shrink sealing

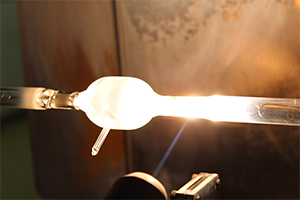

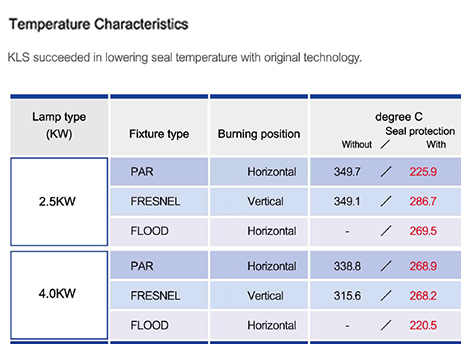

Protecting Sealing Area

One of the failures that can occur during operation of metal halide lamps is sealing breakage. Metal oxidization of the sealing area is the cause of this failure. KLS has applied the technology to all metal halide products where the lamps can lower temperature of sealing part regardless of kinds of fixtures used.

KLSirius Lamp (Xenon/Xenon Mercury Lamps)

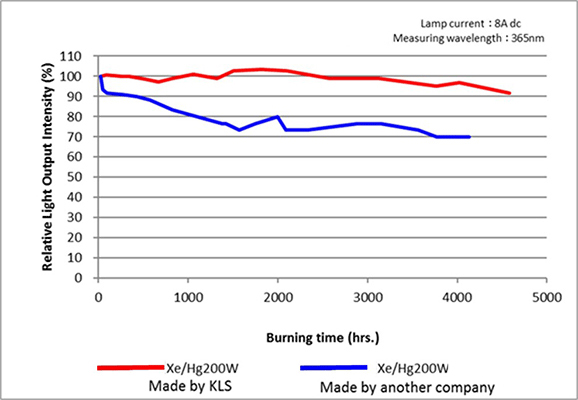

With its ability to emit continuous wide spectrum, from UV to IR regions, DC Xenon lamps and mercury xenon lamps are used in various industrial devices, such as steppers, visual inspection and analytical devices. Stable amount of light emission, long life and high efficiency are key factors for these applications.

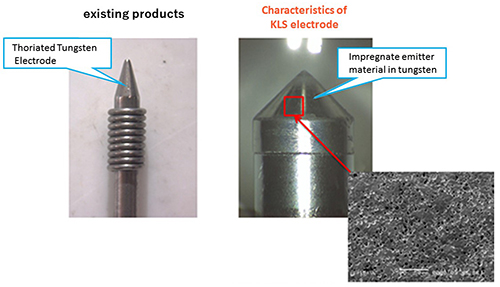

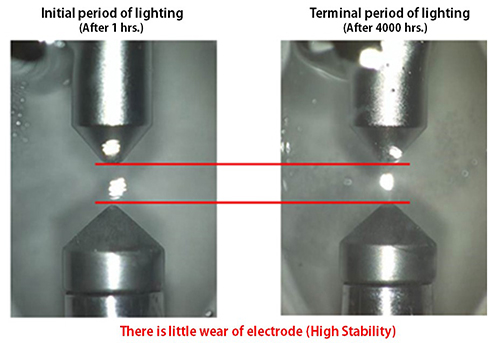

The use of Thoriated Tungsten for cathode materials had caused arc fluctuation and greater electrode wear. By impregnating emitter material in tungsten which is an electrode matrix, we have succeeded in developed high-quality electrode. (Patent pending.)

Characteristics of KLS electrode (compared to existing products)

- Small fluctuation of Cathode spot

- Small fluctuation of arc

- Small fluctuation of light intensity

- Small lamp voltage fluctuation

- High efficiency

- Less wear in tip

- Less attenuation of light intensity

- Long life

- Thoriated Tungsten Electrode and KLS’ Electrode

- Lifetime Characteristics of Xe/ Hg 200W Lamps

- Wear status of electrode after Xe/Hg200W lamp’s life test

Stable light output throughout lifetime. Coustomers can rely on our products.